CTE - Precision Machining & Welding

| Introductory Course for this Pathway |

|

Introduction to S.T.E.M. (Science, Technology, Engineering & Math) 1020 1 Credit Grade 9 & 10 This one-semester course provides a sampling of topics covered in our STEM programs as well as foundational STEAM topics. There are six areas of focus which include mechanical engineering, civil engineering, manufacturing engineering, electrical engineering, robotics, and architecture. A major strength of the course is its emphasis on hands-on experience, teamwork, and problem-solving. To achieve this, students follow the engineering design process in a sequential order starting with basic design and going all the way to model fabrication. Prerequisite: none |

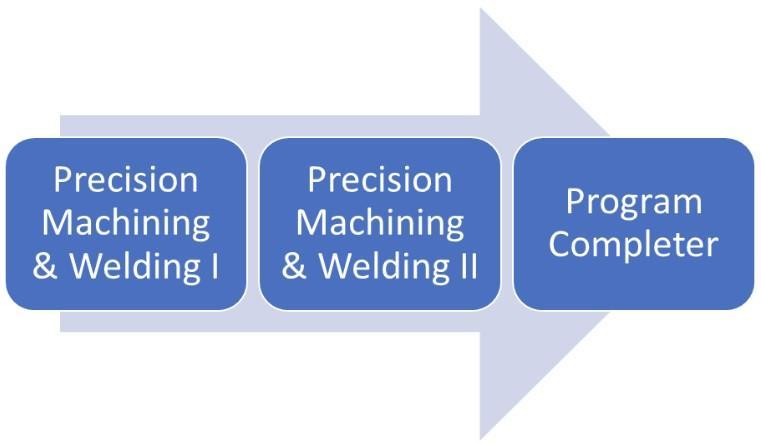

Precision Machining & Welding I 1777

Precision Machining & Welding I 1777

2 Credit Full-Year Grades 10-11

Precision Machining & Welding runs the full academic year (two semesters.) During the first semester students enrolled in this first class will learn basic blueprint reading & measuring techniques. They will be introduced to basic hand tools and a variety of state of the art machines used in modern manufacturing. The safe and proper way to employ all tools and machines is an important component of this course. Students will have the opportunity to become OSHA-10 certified. Basic TIG welding safety and skills will be used, along with machining to create solutions to problems in a collaborative environment.

During the second semester students will further build upon their skills and apply them to more complex and challenging operations. Material properties and machine speeds and feeds will be emphasized. Students will develop spatial intelligence, problem solving and Conversational Computer Numeric Control (NC/CNC) programming skills. Throughout the course, emphasis should be placed on safety, precision, and adherence to industry standards. Guest speakers from the precision machining and welding industries could be invited to provide real-world insights. Additionally, field trips to local machining facilities may enhance students' understanding of the industry.

Prerequisite: One credit in math with a grade of “C” or better.

College Credits: Early College credits available through Nashua Community College

Precision Machining & Welding II 1781

Precision Machining & Welding II 1781

2 Credits Full-Year Grades 11-12

Precision Machining & Welding II also runs the full academic year (two semesters). This is an introductory college level course in machine tool processes and theory. This course provides more in-depth instruction and practice on all of the basic machine tools and introduces the cutting edge technologies that enable manufacturing to create the products our technology-driven society demands. CNC programming and operations will be expanded to include complex projects and Computer Aided Machining (CAM.) The LEAN concepts that drive the modern advanced manufacturing environment will be woven into the course.

Prerequisite: Precision Machining I with a grade of “C” or better and instructor approval.

College Credits: Early College credits available through Nashua Community College

Program Assistantships or Independent Study opportunities may be available to selected students for credit. Students that completed the Precision Machining Program should discuss these possibilities with the instructor.

|

CTE Work Based Learning 1/2 Credit* 1 Credit* Grades: 11 - 12 Work-Based Learning (WBL) provides advanced CTE students the opportunity to learn about the world of work. Students will develop and enhance essential 21st century workforce skills to become industry-ready. CTE WBL empowers students with real work experience, under the supervision of an approved work-site mentor, and the guidance of their CTE instructor. Advanced CTE classwork is meant to supplement and complement this WBL experience, therefore it is expected that students will attend CTE class when scheduled and complete all work as assigned. Credit will be awarded based on satisfactory evaluations from their site supervisor, participation in seminars, completion of related assignments & the number of verified WBL hours. The student is expected to meet with the Career Development Specialist regularly during TASC to review work performance goals, timesheets, journal entries, and capstone project. Students will be required to present their approved capstone project to a panel of mentors, Career Development Specialist, and partnering CTE instructor for final evaluation. |